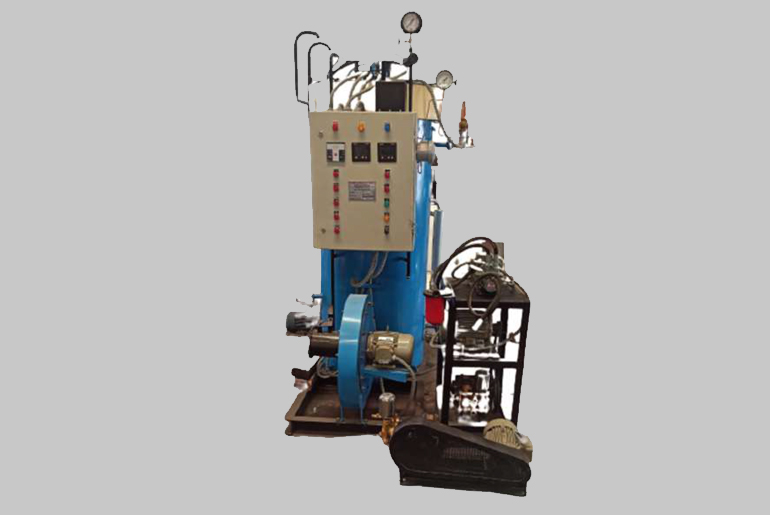

Non and IBR Steam Boilers Manufacturers in Telangana

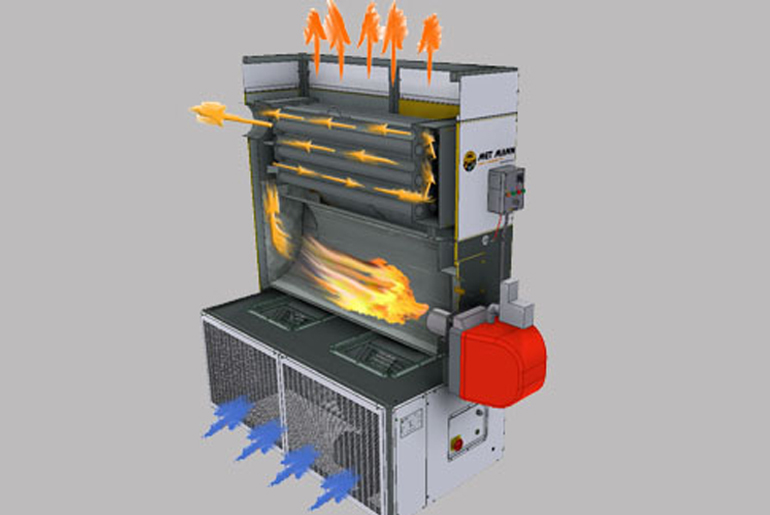

Leading Manufacturers and Suppleirs of IBR Steam Boiler, Non Ibr Boiler, Non Ibr Boiler in Hyderabad Telangana Telangana. IBR (Indian Boiler Regulations) steam boiler is a type of boiler that is designed and manufactured as per the standards set by the Indian government. These regulations were formulated to ensure the safety and efficiency of steam boilers used in various industries such as power generation, chemical, textile, and food processing. IBR steam boilers are crucial for the smooth functioning of industries as they provide the necessary heat and energy for various processes. They are a vital component of any industrial setup and play a significant role in the production and manufacturing process. One of the essential aspects of IBR steam boilers is their compliance with safety regulations. These regulations aim to prevent accidents and ensure the safety of workers and equipment. The Indian Boiler Regulations were first introduced in 1950 and have been regularly updated to keep up with the changing technology and industrial needs. IBR steam boilers are designed and manufactured to be highly efficient, which means they use less fuel and produce more steam. This not only saves costs for the industries but also reduces their carbon footprint, making them environmentally friendly.

One of the key components of an IBR steam boiler is the pressure vessels. These vessels are designed to withstand high pressure and temperature, making them suitable for various industrial applications. The pressure vessels are made of high-quality materials such as carbon steel, stainless steel, or alloy steel, ensuring their durability and longevity. Another crucial aspect of IBR steam boilers is their strict adherence to quality standards. These boilers undergo rigorous testing and inspection procedures to ensure they meet the required standards. This includes testing of materials, welding, and other components to ensure they can withstand high pressure and temperature. IBR steam boilers also come with various safety features such as pressure gauges, safety valves, and water level indicators. These features help in monitoring and controlling the pressure and temperature of the boiler, preventing any accidents or mishaps. One of the significant advantages of IBR steam boilers is their versatility. They can be used for a wide range of applications, from heating water to producing steam for various industrial processes. They can also use various types of fuels such as coal, gas, and oil, making them suitable for different industries and their specific needs. In addition to their safety and efficiency, IBR steam boilers are also cost-effective. They have a longer lifespan compared to other types of boilers, and their maintenance costs are relatively low. This makes them a preferred choice for industries looking for a reliable and cost-effective solution for their steam generation needs. However, like any other equipment, IBR steam boilers also require regular maintenance and servicing to ensure their efficient functioning. Regular inspections, cleaning, and repairs are necessary to keep the boiler in good condition and prevent any breakdowns. In conclusion, IBR steam boilers are an integral part of the industrial sector in Telangana. They play a crucial role in the smooth functioning of various industries and are designed to meet the highest safety and quality standards. With their efficiency, versatility, and cost-effectiveness, they are a preferred choice for industries looking for a reliable and sustainable solution for their steam generation needs.

Overall, the non IBR steam boiler is an ideal choice for many industrial applications. It is a reliable and cost-effective option that does not require the same level of certification as an IBR boiler. Additionally, non IBR steam boiler is relatively safe to use and easy to maintain